Pointing is a critical aspect of architectural stonemasonry, a craft that has been practiced for centuries and continues to be an essential part of modern construction. This process involves the finishing of mortar joints between stones or bricks in masonry construction. The term ‘pointing’ can also refer to the repair of existing joints that have been damaged over time.

Pointing serves both aesthetic and functional purposes. It enhances the visual appeal of the masonry work, providing a neat, finished look. More importantly, it protects the masonry from weather and other external factors, which can cause significant damage over time. This article will delve into the intricacies of pointing in architectural stonemasonry, covering its history, techniques, materials, tools, and more.

Historical Overview of Pointing

The practice of pointing has a long history, dating back to ancient civilisations. The Greeks and Romans, for example, used a form of pointing in their stone and brick constructions. Over the centuries, the techniques and materials used in pointing have evolved, reflecting changes in architectural styles and construction technologies.

In the Middle Ages, for instance, masons would often use a mixture of lime and sand for pointing. This material, known as lime mortar, was easy to work with and provided a durable finish. However, it was susceptible to weathering and would need to be replaced every few decades.

Pointing in the Industrial Age

The Industrial Revolution brought significant changes to the practice of pointing. The development of Portland cement in the 19th century, for example, provided a stronger and more durable alternative to lime mortar. This new material could withstand harsher weather conditions and required less frequent replacement, making it a popular choice for pointing.

However, the use of Portland cement was not without its drawbacks. The material was harder and less flexible than lime mortar, which could lead to damage in the masonry work over time. Furthermore, the stark white colour of Portland cement was often seen as less aesthetically pleasing than the softer hues of lime mortar.

Modern Pointing Techniques

In recent years, there has been a resurgence of interest in traditional pointing techniques and materials. Many modern masons prefer to use lime mortar for pointing, appreciating its flexibility, durability, and aesthetic qualities. At the same time, new technologies and materials have also been developed, offering a range of options for different types of masonry work.

For example, some masons now use a type of mortar known as hydraulic lime, which sets through a chemical reaction with water. This material offers the flexibility and aesthetic appeal of traditional lime mortar, but with improved strength and durability. Other modern pointing techniques involve the use of synthetic resins or other additives to enhance the performance of the mortar.

Pointing Techniques

There are several different techniques used in pointing, each with its own unique characteristics and applications. The choice of technique depends on a variety of factors, including the type of masonry work, the desired aesthetic effect, and the specific conditions of the construction site.

Some of the most common pointing techniques include flush pointing, recessed pointing, weather struck pointing, and tuck pointing. Each of these techniques requires a different set of skills and tools, and each produces a distinct visual effect.

Flush Pointing

Flush pointing is a simple and straightforward technique, where the mortar is finished flush with the surface of the masonry work. This technique is often used in modern construction, as it provides a clean, minimalist look. However, it requires a high level of skill to achieve a perfectly flat finish.

Flush pointing is typically done with a pointing trowel, a small hand tool with a flat, rectangular blade. The mason applies the mortar to the joints, then uses the trowel to smooth and level the surface. Once the mortar has started to set, the mason will often go over the joints again with a jointing tool, to ensure a perfectly smooth finish.

Recessed Pointing

Recessed pointing is a technique where the mortar is finished slightly below the surface of the masonry work. This creates a shadow effect, which can enhance the visual appeal of the masonry. Recessed pointing is often used in traditional or historic buildings, as it can help to highlight the texture and character of the stone or brickwork.

Recessed pointing requires a high level of skill and precision. The mason must carefully control the depth of the mortar, to ensure a consistent finish across the entire masonry work. This is typically done with a jointing tool, which is used to compress and shape the mortar in the joints.

Materials Used in Pointing

The choice of material for pointing is crucial, as it can significantly affect the performance and appearance of the masonry work. The most common materials used in pointing are lime mortar and Portland cement, each with its own advantages and disadvantages.

Lime mortar is a traditional material that has been used in pointing for centuries. It is made from a mixture of lime, sand, and water, and it sets through a process of carbonation. Lime mortar is flexible and breathable, allowing moisture to evaporate from the masonry work. This can help to prevent damage caused by frost or salt crystallisation. However, lime mortar is less strong than Portland cement, and it can take a long time to set.

Portland Cement

Portland cement is a modern material that has been widely used in pointing since the 19th century. It is made from a mixture of limestone and clay, which is heated in a kiln and then ground to a fine powder. When mixed with water, Portland cement sets through a chemical reaction known as hydration.

Portland cement is stronger and more durable than lime mortar, and it sets more quickly. However, it is also harder and less flexible, which can lead to cracking or other damage in the masonry work. Furthermore, Portland cement is not breathable, which means that moisture can become trapped in the masonry, leading to problems such as damp or frost damage.

Hydraulic Lime

Hydraulic lime is a type of lime mortar that sets through a chemical reaction with water. It is made from a special type of limestone, known as hydraulic lime, which contains impurities such as clay or silica. When mixed with water, these impurities react to form a strong, durable bond.

Hydraulic lime offers many of the advantages of both lime mortar and Portland cement. It is flexible and breathable, like lime mortar, but it is also strong and durable, like Portland cement. Furthermore, hydraulic lime sets more quickly than traditional lime mortar, making it a popular choice for many modern masons.

Tools Used in Pointing

The tools used in pointing are relatively simple, but they require a high level of skill and precision to use effectively. The most important tool is the pointing trowel, a small hand tool with a flat, rectangular blade. This is used to apply and shape the mortar in the joints.

In addition to the pointing trowel, masons also use a variety of other tools in pointing. These include a hawk, a flat board used to hold the mortar; a jointing tool, used to compress and shape the mortar in the joints; and a brush, used to clean excess mortar from the surface of the masonry work.

Pointing Trowel

The pointing trowel is the primary tool used in pointing. It is a small hand tool with a flat, rectangular blade, typically made from steel. The blade is attached to a handle, which is designed to fit comfortably in the hand.

The pointing trowel is used to apply the mortar to the joints in the masonry work. The mason scoops up a small amount of mortar on the edge of the trowel, then presses it into the joint. The flat surface of the blade is then used to smooth and level the mortar, creating a neat, finished look.

Hawk

The hawk is a flat board, typically made from wood or metal, with a handle on the underside. The mason places a small amount of mortar on the hawk, then uses the pointing trowel to scoop up the mortar and apply it to the joints.

The hawk serves several purposes in pointing. It provides a convenient surface for holding the mortar, allowing the mason to work more efficiently. It also helps to keep the mortar at a consistent consistency, which can improve the quality of the pointing work.

Jointing Tool

The jointing tool is a small hand tool used to compress and shape the mortar in the joints. It is typically made from steel or another hard material, and it has a rounded or pointed tip.

The mason uses the jointing tool to press down on the mortar, compressing it into the joint. This helps to ensure a strong, durable bond between the mortar and the masonry work. The jointing tool is also used to shape the mortar, creating a neat, finished look.

Conclusion

Pointing is a critical aspect of architectural stonemasonry, serving both aesthetic and functional purposes. It requires a high level of skill and precision, as well as a thorough understanding of the materials and techniques involved.

Despite the advances in technology and materials, the basic principles of pointing have remained largely unchanged for centuries. The craft continues to be practiced by skilled masons around the world, contributing to the preservation and enhancement of our built environment.

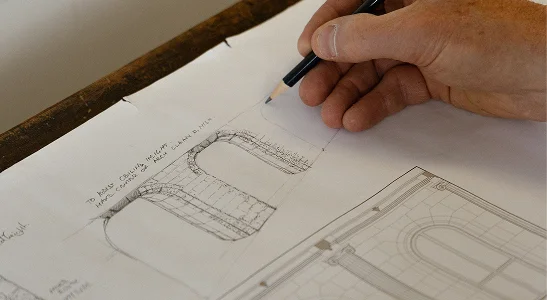

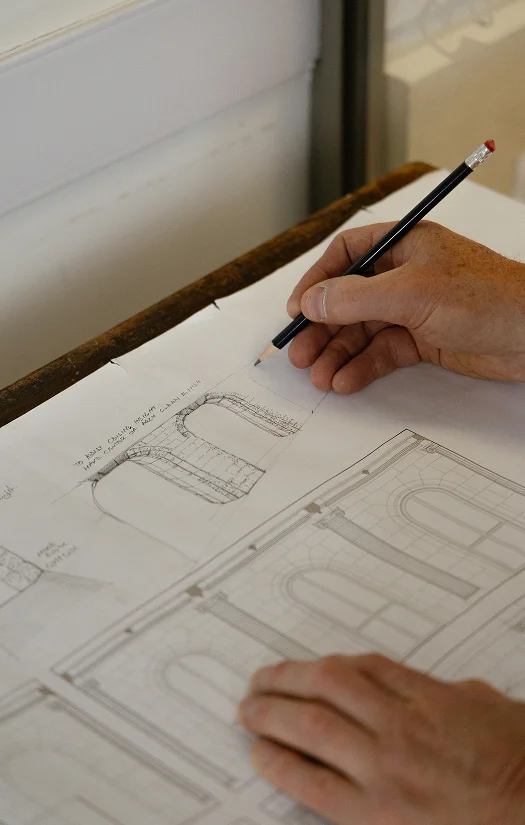

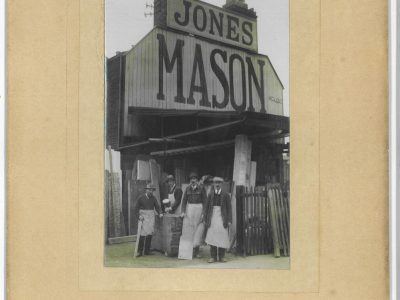

Discover the Art of Pointing with A F Jones Stonemasons

If you’re inspired by the enduring craft of pointing and wish to harness the expertise of seasoned professionals for your next project, look no further than A F Jones Stonemasons. With over 160 years of heritage and a commitment to combining traditional skills with cutting-edge technology, our team is equipped to bring precision, beauty, and longevity to your stonemasonry needs. From grand-scale endeavours to intimate bespoke creations, we invite you to make an enquiry and explore how we can transform your vision into a stone masterpiece.