Jul 13, 2023

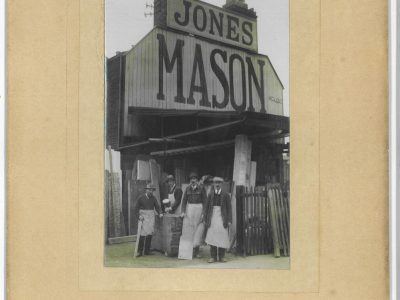

Stonemasonry in 30 objects

Week 14/30: Circular Saws – a primary cutting tool

Primary saws like these play a significant role in the AF Jones production process. They’re capable of cutting large amounts of stone in a short space of time which means we can put projects through at scale, cutting stone to size and shape with good detail before moving on to the banker masons for finishing.

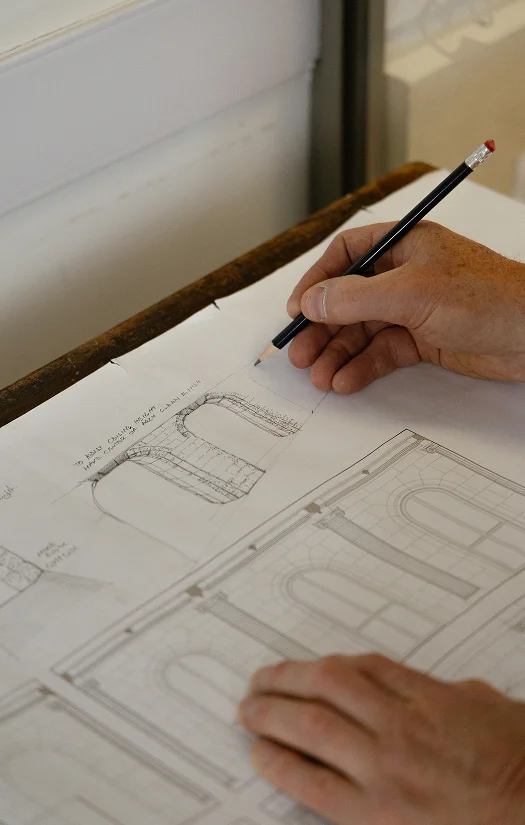

It takes a strong design and production team to make the best of these CNC machines. Our saw masons at AF Jones work closely with our design office where detailed digital drawings are produced which control the cutting process and cut the stone to shape efficiently and with minimal wastage. Once programmed and set to a cutting cycle, the automated process can create a wide range of shapes at quantity: stair treads, columns, cylinders, spheres or shaped blanks for the banker masons to carve in finer detail by hand.

The saw blades themselves are diamond coated and can come in sizes as large as 3 metres in diameter and the one shown here is 1.3 meters in diameter, which is itself considered a large saw blade.

Saw blades spin at a variety of speeds depending on what stone is being cut and the size of saw needed. Hard White marble requires some of the highest tip speeds for the blade – up to 60 m/sec -whilst Hard Basalt can be as low as 30 m/sec.

For our AF Jones Stone Interiors division, it means we can produce precision and high-quality book-matched marble surfaces as well as cutting large surface areas of marble down to size.

Safety is paramount and each saw needs a fully gated enclosure for operation yet despite this, proper use of a circular saw can also help maintain and safer working environment all round in the H&S hierarchy. As well as taking on much of the manual cutting, once completed by masons, its efficient cuts and controlled environment of dust extraction and dampening mean dust is also minimised, which is a priority in any stone workshop.

This is week 14/30 posts in this series. The full series can be found on our LinkedIn profile – or use #stonemasonry30