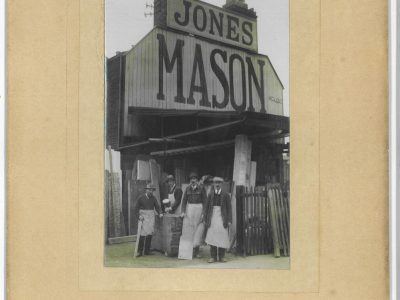

Stonemasonry in 30 objects. 2/30

A router. It’s week two of the series and we’re homing in on the importance of technological advancements in stonemasonry tools. Some might argue using these kinds of tools requires less skill and craft. We think there’s far more to it than that.

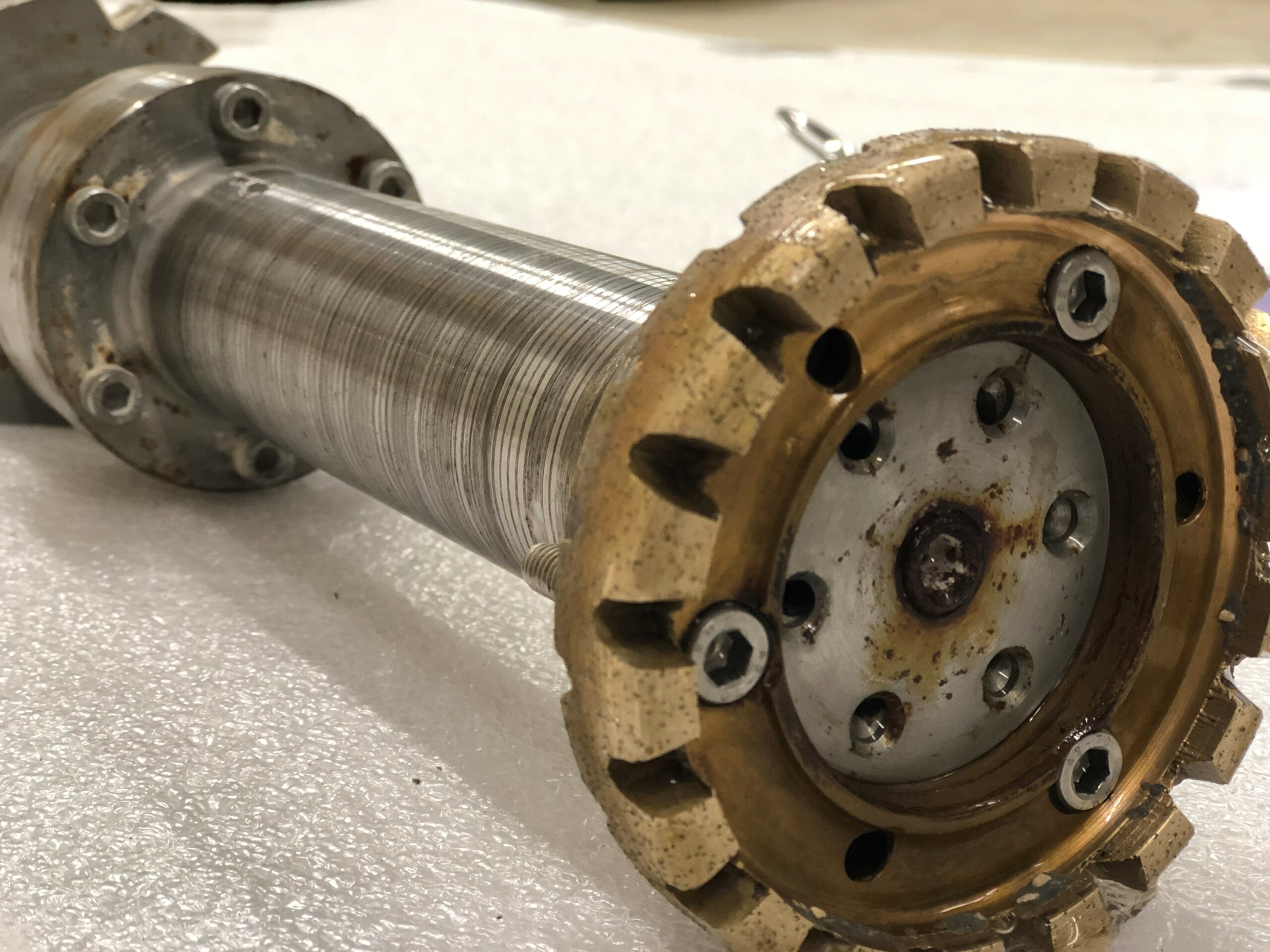

Capable of cutting and shaping stone on an industrial scale, what you see here works stone at up to 6000rpm once fitted to a CNC (computer numerical controlled) cutting machine, profiling and shaping stone down to precise pre-programmed dimensions, operating continuously for days if needed.

The replaceable segmented tool at the sharp end is gold coloured, used for limestone and marble and the flecks set into the metal are the cutting element – sintered diamonds. Routers with silver heads are a harder metal and best suited to sandstone and granite. A careful look at the gold segmented tool here shows its life is nearly done – these parts begin with sharply defined squared-off edges that can be reversed when one side becomes worn and rounded like this one.

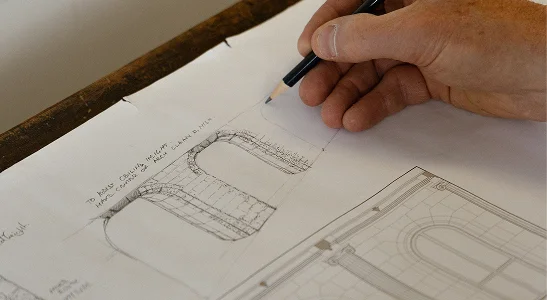

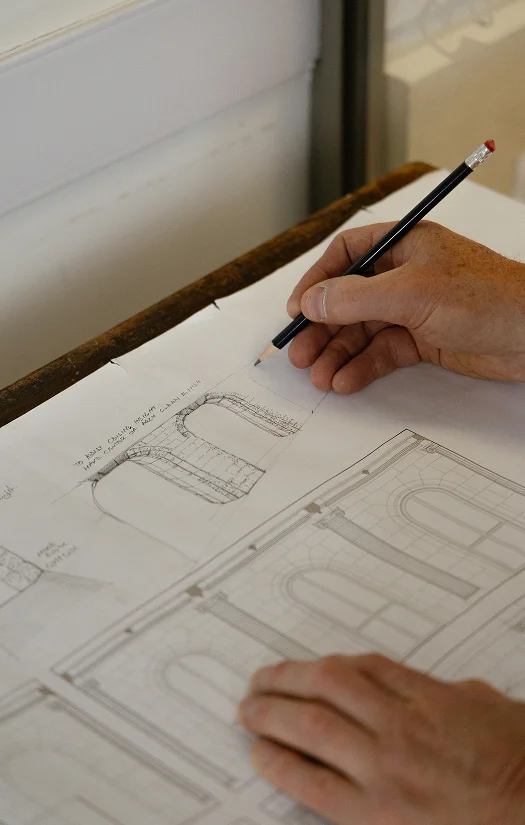

And that’s the easy part. At the heart of it, people and skills still drive our process at AF Jones. Tim, our Production Director has 20 years’ experience with us and heads up our CNC cutting team. Understanding the software required to set up this tool can take up to six months and then years of experience to identify the most efficient cuts, ensuring the stone retains its integrity and material strength throughout its journey from rough stone block out to the banker masons for finishing.

But as technology develops, can the router ever replace the chisel?

This is week 2/30 posts in this series. The full series can be found on our LinkedIn profile – or use #stonemasonry30