Quarrying is a process that involves the extraction of natural stone from the earth. This stone is then used in the construction of buildings, monuments, and other structures. The process of quarrying involves a series of steps, each of which is crucial to the overall success of the project. This article will delve into the intricacies of quarrying, providing a comprehensive understanding of this fundamental aspect of architectural stonemasonry.

The term ‘quarry’ is derived from the Latin ‘quadratum’, which means ‘square’. This is a reference to the fact that stones extracted from quarries are often cut into square or rectangular shapes. However, the process of quarrying is much more complex than simply cutting stone into specific shapes. It involves a deep understanding of the geological properties of the stone, the appropriate techniques for extraction, and the subsequent processes involved in preparing the stone for use in construction.

The Geological Considerations

Understanding the geological properties of the stone to be quarried is a fundamental aspect of architectural stonemasonry. This involves an assessment of the stone’s hardness, grain, color, and other physical properties. These properties will determine the suitability of the stone for various uses in construction.

Additionally, the geological considerations also involve an understanding of the formation of the stone. This includes knowledge of the geological processes that led to the formation of the stone, such as sedimentation, metamorphism, and volcanic activity. This knowledge is crucial in determining the best methods for extracting the stone from the earth.

Hardness and Grain

The hardness of a stone is a measure of its resistance to scratching or abrasion. This is a crucial factor in determining the stone’s suitability for various uses in construction. For example, softer stones may be more suitable for decorative elements, while harder stones may be used for structural elements.

The grain of a stone refers to its texture, which is determined by the size and arrangement of its constituent minerals. The grain of a stone can affect its appearance and its workability. For example, a stone with a coarse grain may be more difficult to work with than a stone with a fine grain, but it may also have a more distinctive appearance.

Colour and Other Physical Properties

The colour of a stone is determined by the presence of various minerals and compounds. For example, iron oxides can give a stone a reddish colour, while carbon can make a stone black. The colour of a stone can greatly affect its aesthetic appeal, and is therefore a crucial consideration in architectural stonemasonry.

Other physical properties of a stone that may be considered include its density, porosity, and permeability. These properties can affect the stone’s durability, its resistance to weathering, and its suitability for various uses in construction.

The Quarrying Process

The process of quarrying involves several stages, each of which requires a different set of skills and equipment. The first stage is the identification of a suitable quarry site. This involves geological surveys to determine the quality and quantity of the stone available at the site.

Once a suitable site has been identified, the next stage is the extraction of the stone. This involves the use of heavy machinery and explosives to remove the overburden (the soil and rock covering the stone) and to break the stone into manageable pieces.

Extraction Techniques

The techniques used for extraction depend on the type of stone and the specific conditions at the quarry site. For example, softer stones may be extracted using a technique known as ‘plug and feather’, which involves drilling holes into the stone and then inserting wedges to split it.

For harder stones, a technique known as ‘blasting’ may be used. This involves the use of explosives to break the stone into smaller pieces. The use of explosives requires a high degree of skill and care, as improper use can result in damage to the stone and pose a risk to safety.

Post-Extraction Processes

Once the stone has been extracted, it must be processed before it can be used in construction. This involves cutting the stone into the desired shapes and sizes, and finishing the surfaces to achieve the desired appearance.

The methods used for cutting and finishing the stone depend on its properties and the desired end result. For example, a stone with a coarse grain may be cut with a saw, while a stone with a fine grain may be cut with a chisel. The surfaces of the stone may be finished by grinding, polishing, or other methods to achieve the desired texture and shine.

The Role of Quarrying in Architectural Stonemasonry

Quarrying plays a crucial role in architectural stonemasonry, as it provides the raw material for the construction of buildings, monuments, and other structures. The quality of the stone extracted from a quarry can greatly affect the quality of the finished structure.

Furthermore, the process of quarrying itself can have a significant impact on the environment. Therefore, it is important for architectural stonemasons to use sustainable quarrying practices, such as minimising waste, reducing energy consumption, and rehabilitating quarry sites after extraction.

Quality of Stone

The quality of the stone extracted from a quarry is determined by a number of factors, including its geological properties, the techniques used for extraction, and the post-extraction processes. A high-quality stone will have a consistent colour and grain, and will be free from defects such as cracks or inclusions.

It is the responsibility of the architectural stonemason to ensure that the stone extracted from a quarry meets the required standards of quality. This involves careful selection of the quarry site, meticulous extraction techniques, and rigorous quality control processes.

Sustainability in Quarrying

Sustainability in quarrying involves a number of practices aimed at minimising the environmental impact of the quarrying process. These include reducing energy consumption, minimising waste, and rehabilitating quarry sites after extraction.

Reducing energy consumption involves the use of energy-efficient machinery and equipment, and optimising the extraction process to minimise the amount of energy required. Minimising waste involves the efficient use of the stone extracted from the quarry, and the recycling or reuse of waste materials. Rehabilitating quarry sites involves restoring the land to its original condition or adapting it for other uses after the extraction process is complete.

Conclusion

Quarrying is a fundamental aspect of architectural stonemasonry, providing the raw material for the construction of buildings, monuments, and other structures. It involves a deep understanding of the geological properties of the stone, the appropriate techniques for extraction, and the subsequent processes involved in preparing the stone for use in construction.

While the process of quarrying is complex and requires a high degree of skill and knowledge, it is crucial to the success of any architectural stonemasonry project. By understanding the intricacies of quarrying, architectural stonemasons can ensure the quality of their work and contribute to the sustainability of their industry.

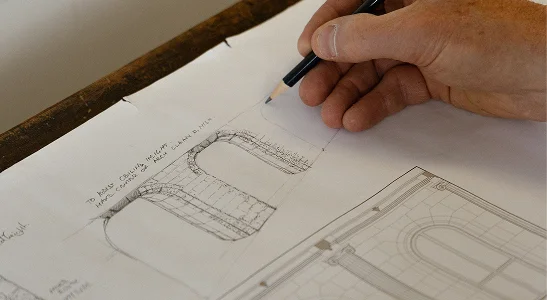

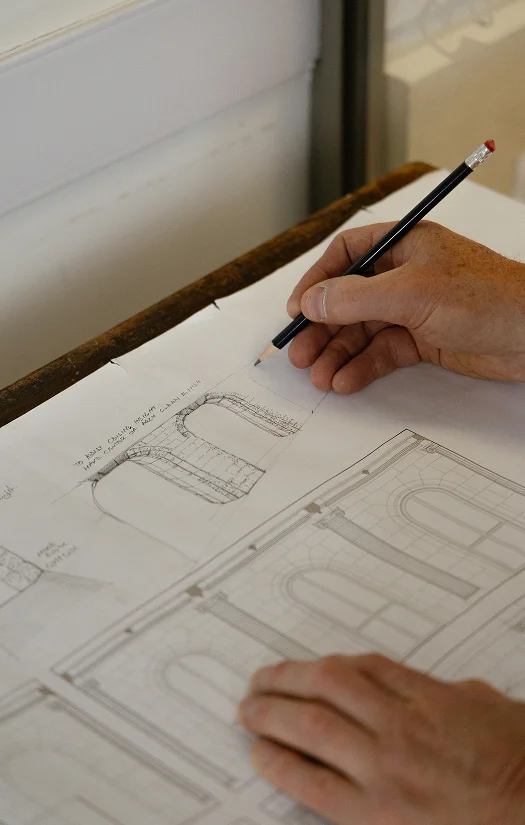

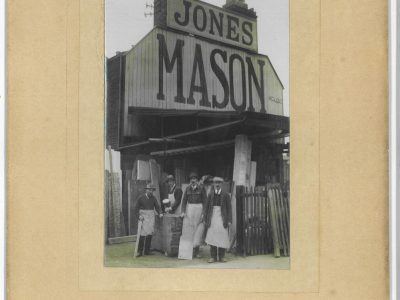

Discover the Art of Stonemasonry with AF Jones

Embark on a journey to transform your architectural vision into reality with the expertise of AF Jones Stonemasons. With over 160 years of heritage and a blend of traditional craftsmanship and modern technology, we stand ready to guide you through the full spectrum of stonemasonry services. From the initial concept to the final touches of installation, our knowledgeable team is dedicated to realising the potential of stone in your project. Whether it’s a grand-scale development or a bespoke private commission, we have the capacity and the passion to deliver excellence. Visit our showroom or make an enquiry today to explore how we can elevate your next project with the timeless elegance of stone.